Aluminum Furniture with the Highest Weather Resistance in the World

Leading up to our 30th anniversary, we are celebrating the most revolutionary moments of McKinnon and Harris so far.

LOOKING AT ALUMINUM THROUGH A NEW LENS

Co-founders and siblings Anne and Will admit that they had a bit of a preconception about aluminum in the early days of the company. They first began building furniture in wrought iron, largely because old and enduring antique garden pieces were made in this material. They believed aluminum to be “cheap,” but they will tell you now, they were wrong. Aluminum is not an inferior material, rather, the outdoor furniture industry has used it in ways that result in mediocre quality furniture. The industry standard had been to utilize either cast aluminum or a very thin, easily bendable, low-grade variant of the material. Furniture made from this lower quality aluminum was not built to last. It was being bought and sold with a disposable mentality, a mentality which was becoming more a part of societal norms.

Dismayed by this, Will and Anne thought back to when furniture pieces were created to be heirloom quality, passed on through many lifetimes. A garden takes a lifetime of cultivation – and great gardens never happened overnight. They began exploring crafting techniques used to build enduring wooden furniture and applied that approach to how they worked with aluminum.

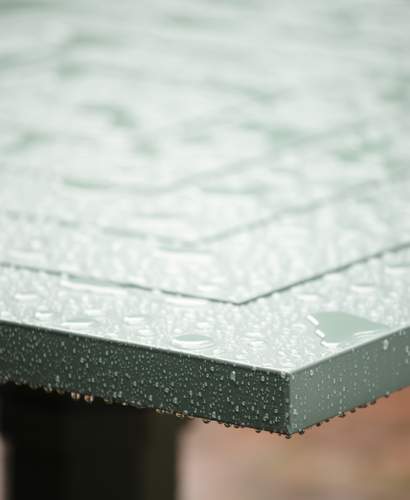

FOR THE FIRST TIME: ALUMINUM FURNITURE IMPENETRABLE TO CORROSION

The pièce de résistance? Performance. Performance and innovation are driving forces in the workshop, dictating a continual quest of how to craft a product to perform for a lifetime. McKinnon and Harris furniture fulfills the remarkable task of remaining outdoors year-round in even the most demanding exterior environments – from Palm Beach to Dubai. Our pieces are heirloom quality, built to be enjoyed for generations. To ensure this, we protect our uncompromising craftsmanship with exceptional high performance coatings. More than a quarter century of our research and development have led to the creation of the most effective, environmentally friendly coating applications for corrosion resistance.

In 2018, we began employing Bonderite® EC² Technology as the initial undercoating in our multi-step architectural coating system. We are proud to be the first and the only exterior furniture company to implement this revolutionary coating technology from Henkel Corporation. The salt spray resistance of this coating creates a more durable finish compared to traditional technologies used in the market today. It adds tremendous value to the life of the furniture, maintaining the integrity of each aluminum frame.

By making furniture with an exceptionally long lifecycle, we avoid contributing to the landfill with obsolete, broken, cast-off things. We are so certain of our unsurpassed craftsmanship that we guarantee our handmade aluminum furniture for life.

Just like us, our all-weather furniture likes to be pampered from time to time, which is why we offer a spa treatment. At our spa, we strip your furniture to bare bones, repair any imperfections, replace hardware, recoat, and bring it up to the most recent, high caliber standards – which include the EC² undercoating. We ship the furniture back to you looking like the day you first received it.